Colmac Heat-Pump

Water Heaters

Heat Pumps Optimize Efficiency in Domestic Hot Water Production

Conventional Water Heating is Inefficient

Heating water in New York City’s buildings can be expensive and harmful to the environment, especially if fossil-fuel-burning heaters or furnaces are used. In fact, older heaters can waste up to 20% of their fuel, and even newer models can waste up to 10%. This results in more money spent and more carbon emissions released into the environment.

Heat Pumps: A Better Way for Water Heating

Heat pumps use the same operating principle as an air-conditioner or refrigerator. Utilizing electricity and compressors, they absorb energy from air or water, and transfer it into domestic water at useable temperatures. Heat-pump water heaters enable buildings to energy efficiently heat water to temperatures as high as 185°F in a single pass.

Heat-pump water heaters are the best alternative for conserving energy. This is because they move heat with a heat pump, rather than generating it via fossil fuels or electric resistance. Depending on the air- or water-source temperature, water can be heated using 1/3-1/4 of the energy required by gas or electric resistance.

Colmac Heat Pumps are the Optimal Choice

Colmac’s electric heat-pump water heaters (HPWHs) are the optimal choice for domestic water heating for the following reasons:

- Energy-efficient water heating: Heat-pump water heaters maximize energy efficiency and have a significantly higher Coefficient of Performance (COP) than gas or electric-resistance systems. Colmac systems are the most efficient method available today for heating domestic water. They typically achieve COPs of 4-6, compared to the most-efficient boiler, which only reaches .95. This means that Colmac heat-pump water heaters are up to 600% more efficient than conventional options.

- Supporting sustainability and building electrification: Heat-pump water heaters’ extremely high COPs make them a green, sustainable water-heating option. They drastically cut energy consumption and don’t require fossil fuels. Installing Colmac systems supports building electrification, a central part of NYC 80×50 and the NYC Green New Deal. These initiatives seek to cut greenhouse gas emissions 80% by 2050 and 30% by 2030, respectively. In addition, the Colmac high-efficiency vapor compression cycle has zero direct carbon emissions. As a result, it can be part of a LEED points design and/or qualify for environmental utility incentives or credits.

- Recovering otherwise-wasted heat: One of the main sources for Colmac heat-pump water heaters is heat coming from other HVAC operations. This heat energy would otherwise be expelled into the atmosphere and wasted. Such heat sources include building exhaust systems, chillers and cooling towers. Utilizing this waste heat further bolsters efficiencies and environmental protection.

- Significant cost savings: With heat pumps, three to five units of energy are moved from the source to the process water for every electrical-power input. And with ample thermal storage, much of the cost can be shifted to off-peak hours. What’s more, while heating potable water, Colmac systems create cool air or cold water, which simultaneously reduces cooling costs. This means that by using Colmac heat-pump water heaters, a building’s hot-water production can be cash-flow positive.

- Reliable performance: Designed for low maintenance and easy service, Colmac heat-pump water heaters have a life expectancy of 15+ years. In fact, many units last over 25 years. The Colmac WaterHeat single-pass system delivers a constant leaving-water temperature for continuous water heating whenever the unit is running.

- Safe and sanitary water: Safe for potable domestic water systems, the double-wall-vented condensers used by Colmac fully isolate the refrigerant from the water system. By heating water to 140°F-185°F in a single pass, Colmac WaterHeat creates a Hazard Analysis and Critical Control Point (HACCP). This ensures the eradication of Legionella in hot-water storage systems without the use of UV or chemicals.

- Fulfilling NYC energy code:Section C403.4.6 of the 2014 NYC Energy Conservation Code indicates that “condenser-water heat recovery must be installed for heating service water if the total installed heat capacity of the water cooled system exceeds 6,000 MBH of heat rejection.” This equates to approximately 400 tons of installed cooling capacity. Engineers find this portion of the code to be difficult to comply with because it’s contrary to the economizer code. The issue becomes: how do you preheat domestic water in the cooler months when the condenser water is cold? Colmac solves this problem because, even with 45°F water, its systems can create 140°F+ domestic hot water. Not only does this comply with the code, but it exceeds it drastically.

Applications for Colmac Heat-Pump Water Heaters

Colmac heat pumps for domestic hot water can be used in a variety of applications, including:

- Air-source heat-pump water heaters: Hotels, apartments, offices, dormitories, laundry facilities, hospitals, schools, industrial processes, pools and hydronic heating.

- Water-source heat-pump water heaters: Hotels, apartments, offices, dormitories, potable water cooling, hospitals, schools, industrial processes, geothermal and hydronic heating.

- Mechanical and plumbing engineers: For mechanical and plumbing engineers, when a building is air-cooled or using variable refrigerant flow (VRF), Colmac heat-pump water heaters are a smart selection.

PRODUCTS

Colmac CxA – Modular Air-Source Heat-Pump Water Heater

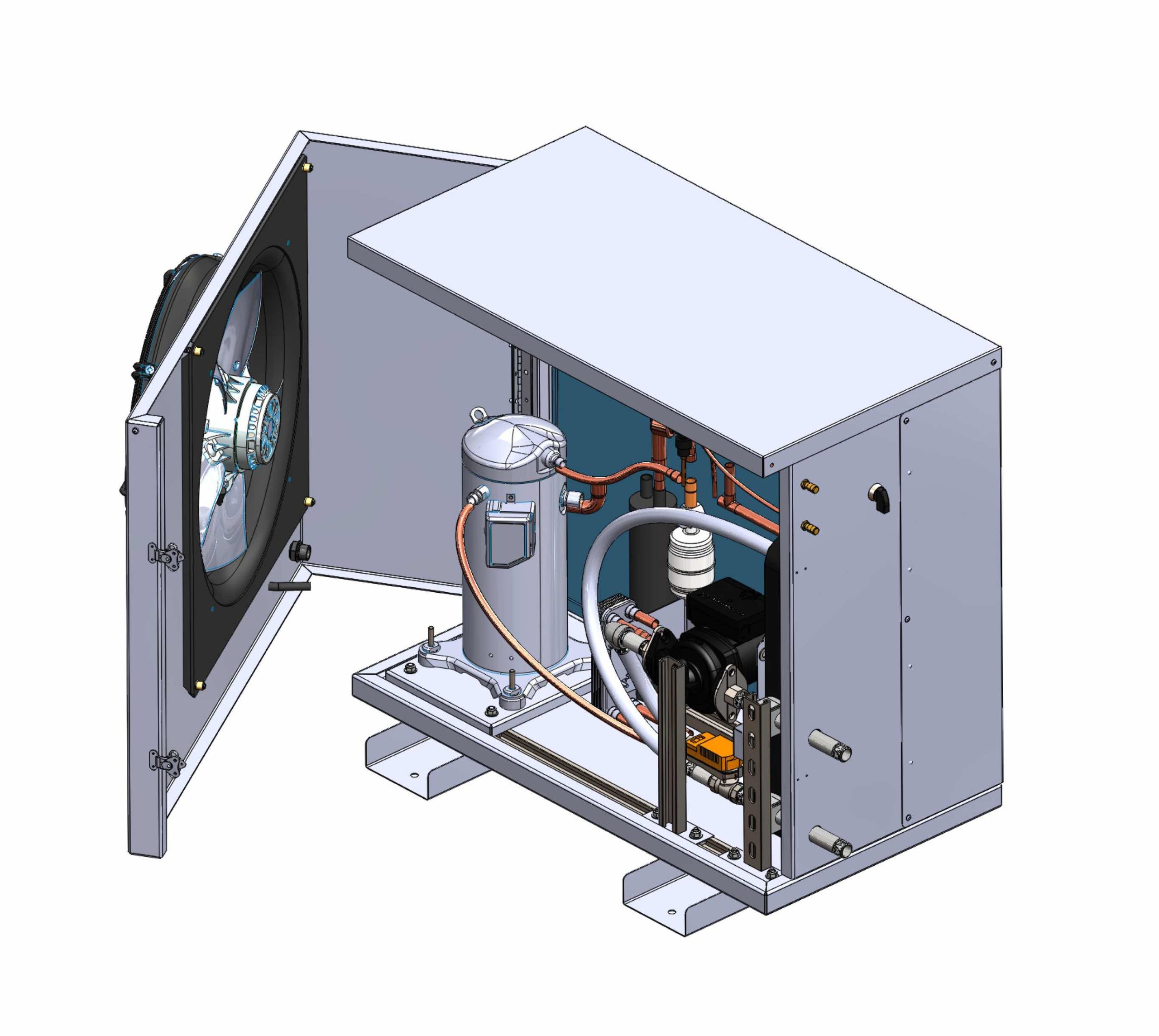

The CxA series is the next generation of air-source heat pumps from Colmac WaterHeat. This represents a leap forward in controls and operation from the previous HPA design.

Models include compressors from 10 to 30 hp, with optional VFDs to provide turndown and soft-start capabilities. ECM propeller fans come standard, with optional ECM plenum fans that can accommodate up to 3″ of external static pressure. Modifications to the refrigeration circuit allow the CxAs to operate with air temperatures 10°F lower than HPA units.

CxA units are modular with a taller profile and reduced footprint design. CxA-10 and -15 models are designed to fit through a standard 36″ door and inside most elevators for easier installation, particularly in retrofit applications. CxA units require no service clearance on the sides, allowing them to be placed next to each other in arrays of up to eight units. The units’ slide-out drawers allow for in-place servicing of the refrigeration components. As with all Cx series units, individual unit controllers can interconnect via ethernet to perform their own staging, run-time balancing and BMS communications.

To improve COPs and improve hot water output, the CxA series has a completely redesigned defrost system. Hot-gas defrost has been added to the evaporator, cutting defrost times to mere minutes. New intelligent defrost controls monitor operating conditions so units only go into defrost mode when necessary.

Colmac CxV – Low-Temp Air-Source Heat-Pump Water Heater

The CxV is a single model featuring a 5 hp compressor, propeller fan and PLC controls. Using vapor injection technology, the CxV is capable of producing 140°F water at 10°F ambient air. The unit can continue to operate down to -4°F, producing 120°F water.

The CxV utilizes the same intelligent-defrost control and hot-gas defrost that was developed on the new CxA series. This improves hot water output and minimzes defrost cycles, maximizing COPs.

As with all Cx series units, individual CxV unit controllers can interconnect (up to 8 units) to perform staging, runtime balancing and BMS communications.

The CxV’s swing-out door allows for excellent access to all internal components. It also features external high- and low-pressure measurement ports.

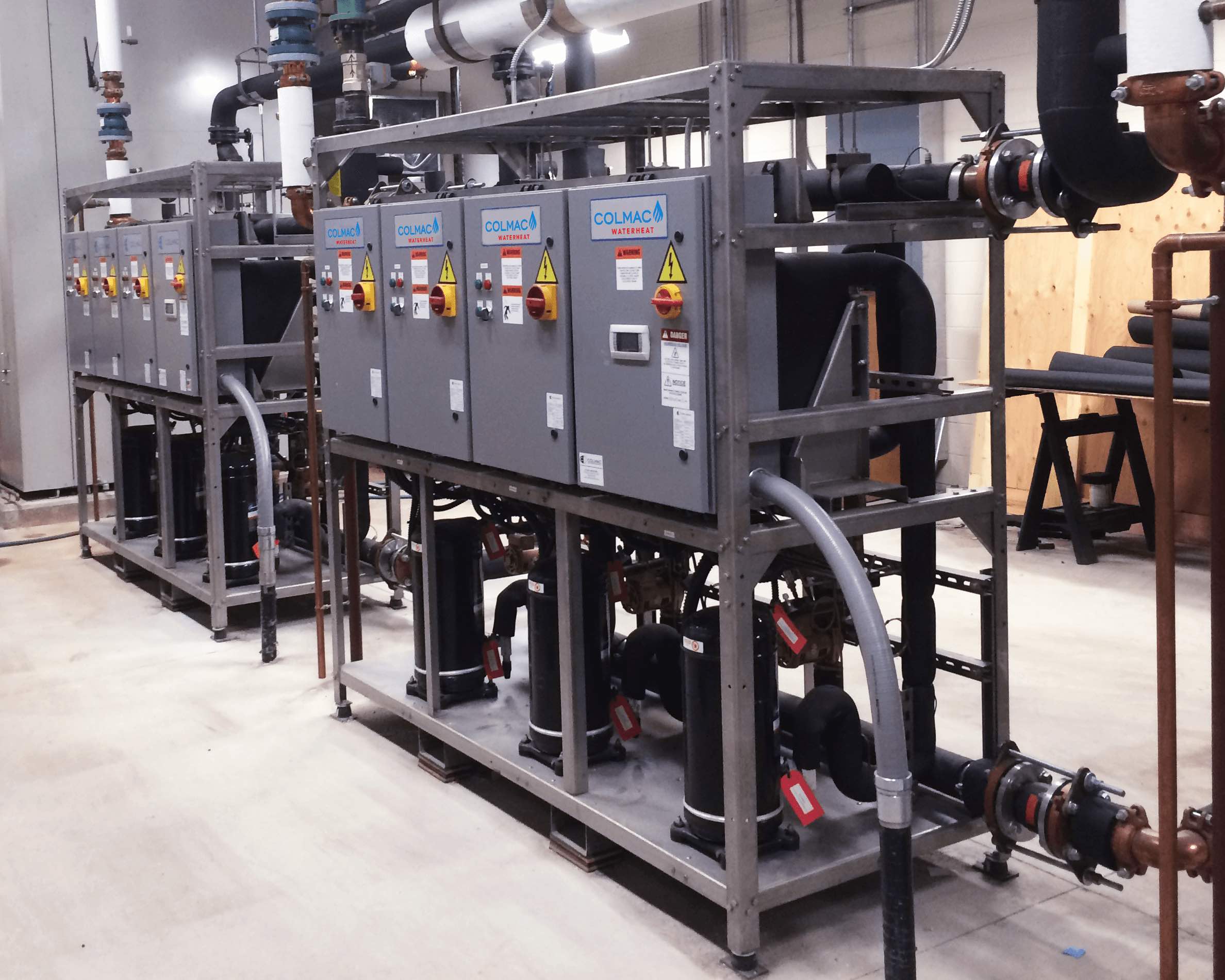

Colmac CxW Series – Modular, Water-Source Heat-Pump Water Heater

Colmac CxW modular water-source heat pumps use energy collected from a fluid stream to heat domestic water to temperatures up to 185ºF.

The source fluid can be any filtered, non-corrosive, pressurized stream of liquid at temperatures as low as 50°F.

CxW modules can be arranged in banks to meet any capacity requirement. Their PLC interconnectivity allows multiple units to act as a single machine.

All CxW models will fit through a standard 36″ door, making them ideal for retrofits and high-rise applications. They are also stackable, doubling the capacity per square foot.

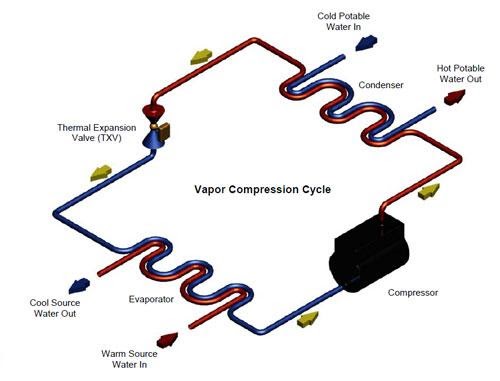

Water-Source Heat Pump Basics

Energy from a pressurized liquid stream is absorbed by refrigerant in the evaporator causing the refrigerant to change phase from a liquid to a gas. This gas refrigerant is then compressed by a compressor that adds temperature and pressure to the refrigerant. The high-temperature, high-pressure refrigerant gas is then condensed to a liquid in a condenser where energy is traded from the refrigerant to sanitary water suitable for human consumption. Finally, the high-pressure liquid refrigerant is passed through an expansion valve that causes the refrigerant’s pressure and temperature to drop so it can once again enter the evaporator and absorb energy from the liquid source.

To maximize the efficiency of a water-source heat pump, use the warmest liquid with highest specific heat and try to deliver the lowest sanitary water temperature acceptable. This minimizes the compressor work, which is the largest operational cost associated with a heat pump. Building hydronic loop water, return chilled water, condenser or cooling tower water, geothermal loops or wells and industrial-process water are a few of the possible heat sources that can be utilized by this heat pump.

Insights

Colmac White Paper

Building Efficiency via Electrification of Domestic Water Heating – The Final Frontier of Sustainability Heat pumps are the only viable carbon-free solution for domestic water heating, and can help make NYC 80×50 goals a reality. The commercial and residential building sector consists of many structures that are inefficient with natural resources…

SHARC Energy Systems Flyer

PIRANHA™ Wastewater Heat Recovery System The PiranhaTM is a self-contained thermal energy recovery system specifically designed to heat domestic hot water by recovering energy contained in wastewater that would otherwise be lost down the drain. Benefits include: Delivers 80% of domestic hot water heating load, ROI in 4-7 years, Environmentally…

Colmac Sales Flyer

Water Source Heat Pumps: Standard Features: Double wall, vented, 316L stainless steel condenser for safe, potable water heating, 140°F – 160°F first-pass output temperatures to prevent and eradicate legionella, Industrial PLC controls, multiple modules can link controls to function as one, Electronic temperature control and expansion valves, Integrated stainless steel circulator…

Technologies

Resources

About Us

© 2023 HIGHMARK | Building Efficiency